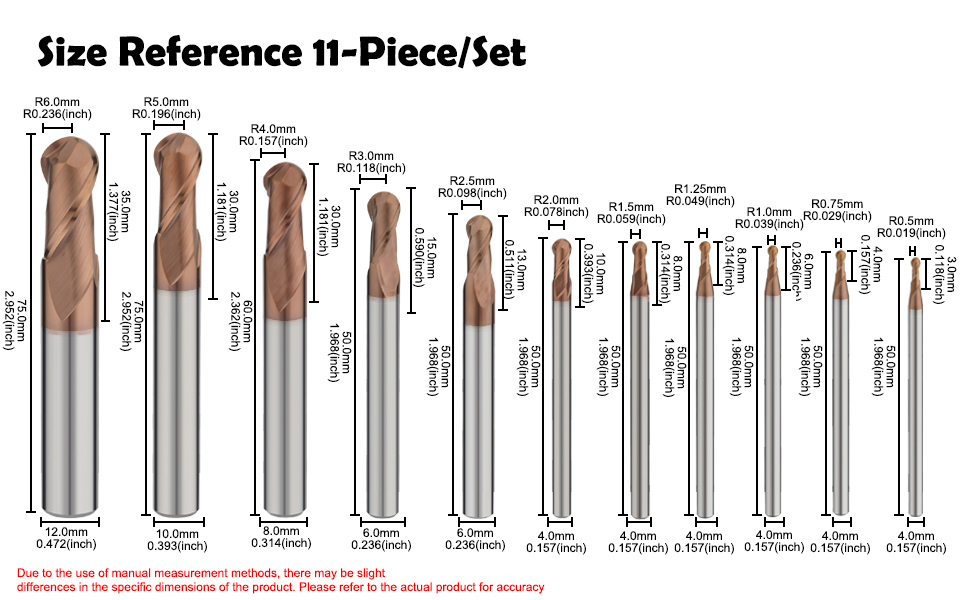

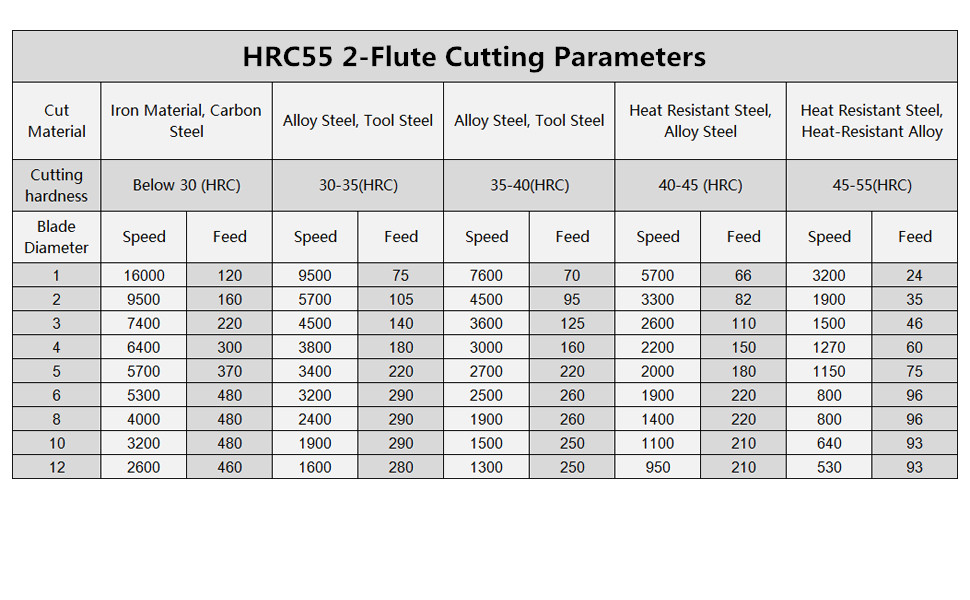

Carbide Ball Nose EndMill HRC55 Double Edge 2 Flute TiAlN Coating Tungsten Steel Milling Cutter for Metal Steel HRC55 R0.5-R6.0 Series 11pcs Set

Shipping calculated at checkout.

Guaranteed Safe Checkout

Description

Product Description

Carbide Ball Nose EndMill HRC55 Double Edge 2 Flute TiAlN Coating Tungsten Steel Milling Cutter for Metal Steel HRC55 R0.5-R6.0 Series 11pcs Set